Understanding The Importance Of Preventing Brake Fluid Loss

Losing brake fluid can cause risks such as reduced braking power, damage to the brake system, and air entering the brake circuit, so it’s crucial to prevent any loss of this vital fluid.Risks Of Losing Brake Fluid

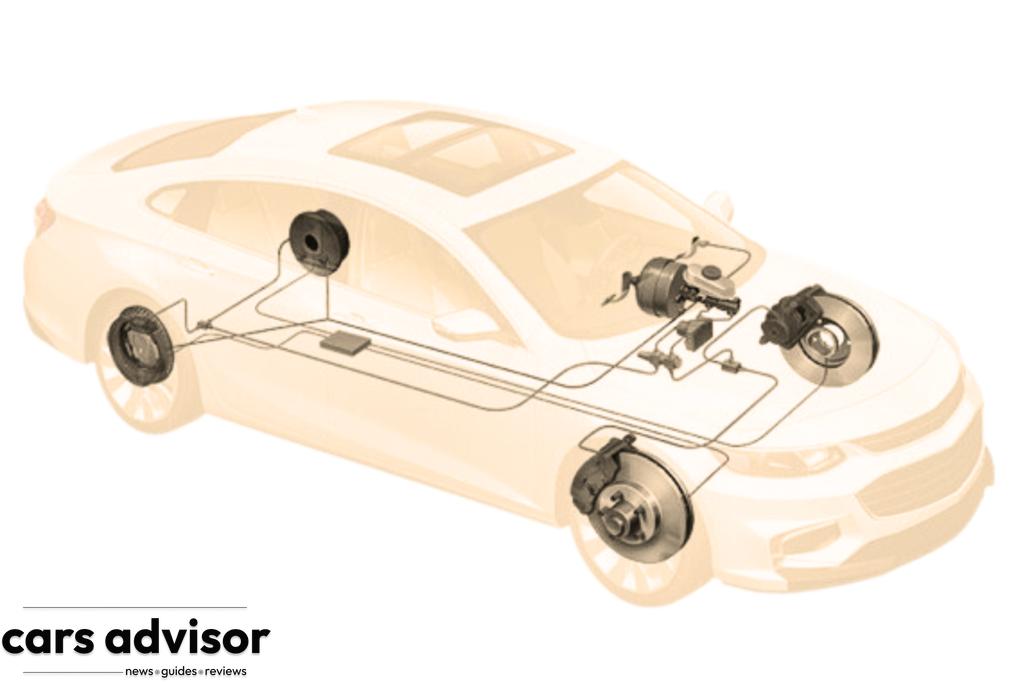

One major risk of losing brake fluid is that it can compromise the performance and safety of your braking system. Brake fluid plays a crucial role in transferring pressure from your foot on the brake pedal to the brake callipers, which ultimately clamp down on the brake pads and produce friction to stop your vehicle. Another concern when dealing with lost brake fluid is its potential damage to surrounding parts and components. Brake fluid is highly corrosive and can eat away at paint, rubber seals, plastic materials, and other sensitive components under your car’s hood.

If left unaddressed for an extended period, this could create additional problems with various systems in your vehicle beyond just the brakes, like causing leaks or corrosion in coolant lines or electrical wiring.

Preventing such scenarios from happening while working on removing a brake line from a calliper without losing fluid requires careful attention during each step I will discuss later in this article.

Another concern when dealing with lost brake fluid is its potential damage to surrounding parts and components. Brake fluid is highly corrosive and can eat away at paint, rubber seals, plastic materials, and other sensitive components under your car’s hood.

If left unaddressed for an extended period, this could create additional problems with various systems in your vehicle beyond just the brakes, like causing leaks or corrosion in coolant lines or electrical wiring.

Preventing such scenarios from happening while working on removing a brake line from a calliper without losing fluid requires careful attention during each step I will discuss later in this article.

Importance Of Preventing Air From Entering The Brake System

Preventing air from entering the brake system is crucial to maintaining your vehicle’s safety and preventing braking issues. Air entering the system creates pockets that compress when you press down on the brake pedal, reducing its effectiveness. To prevent this from happening, it’s essential to keep air out of your brake lines by ensuring there are no leaks or breaks in any part of the system during repair and maintenance needs.

Additionally, when bleeding brakes after any repair work on them should be performed correctly by following manufacturer instructions or getting help from a professional mechanic with experience in such tasks.

It’s also critical that you avoid opening up various fittings beyond what is necessary for repairs to avoid introducing contaminants into your hydraulic fluid line that contains some moisture leading to corrosion if left unattended over an extended period without replacements.

To prevent this from happening, it’s essential to keep air out of your brake lines by ensuring there are no leaks or breaks in any part of the system during repair and maintenance needs.

Additionally, when bleeding brakes after any repair work on them should be performed correctly by following manufacturer instructions or getting help from a professional mechanic with experience in such tasks.

It’s also critical that you avoid opening up various fittings beyond what is necessary for repairs to avoid introducing contaminants into your hydraulic fluid line that contains some moisture leading to corrosion if left unattended over an extended period without replacements.

Steps To Remove Brake Line From Caliper Without Losing Fluid

Follow these steps to safely remove the brake line from your calliper without losing any fluid, ensuring a smooth and hassle-free maintenance process.Gathering The Necessary Tools And Materials

Before removing the brake line from the calliper, gathering all the necessary tools and materials is important. Here’s what you will need:- A catch basin or container to collect any spilt brake fluid

- Wrenches or sockets in the correct size for your specific calliper and brake line fittings

- Brake hose pliers or a clamp to prevent brake fluid from leaking out of the system

- Ziploc bags to keep bolts and other small parts organized and easily accessible

- Teflon tape to wrap around bolt threads when reattaching the brake line

- Brass washers and nuts to replace any worn or damaged parts during reassembly

Loosening The Brake Line Fitting Gradually

To remove the brake line from the caliper without losing fluid, it’s important to loosen the fitting gradually. You don’t want to risk suddenly releasing pressure and allowing brake fluid to spill out. Use a wrench or socket of the correct size to start loosening the fitting slowly. Remember that overtightening can damage threads on both bolt and nut connections, which would result in leaks after installation is complete. Therefore, use Teflon tape on the bolt thread before removing the bolts. You should also be careful not to cross-thread when reinstalling so that they are tight enough yet still easy to remove later when necessary by using brass washers and nuts for secure tightening up securely while preventing rust buildup over time.Clamping The Brake Line Or Using Hose Pliers

One way to prevent brake fluid loss when removing the brake line from the calliper is by clamping the line or using hose pliers. This helps keep the fluid inside and prevents air from entering the brake system, which can cause spongy brakes. One common method is to use a pair of vice grips or hose pliers to clamp off the line on either side of where it will be disconnected. Another option is to use a specialized tool designed specifically for clamping off brake lines. These tools often have adjustable jaws that can grip onto different sizes of lines and apply even pressure, ensuring a secure seal without any damage done to your brake lines.Removing The Brake Line From The Caliper

To remove the brake line from the caliper without losing fluid, begin by loosening the brake line fitting gradually. Start by using a box-end wrench or flare-nut wrench to loosen and unscrew the bolt connecting the brake line to the caliper. Next, clamp down on the brake hose with vice grip pliers or use a specialized hose-clamp tool to stop fluid leaks. Once clamped or plugged in place, you can safely remove your old callipers and replace them with new ones without fear of losing any valuable hydraulic fluid. Remember that it is essential always to bleed your brakes correctly after installing new components like callipers. Bleeding helps remove trapped air bubbles from your braking circuit, which could potentially impair your car’s stopping power if left unchecked.Plugging The Open Brake Line To Prevent Fluid Loss

Once you have successfully removed the brake line from the calliper, it is important to plug the open end immediately to prevent brake fluid loss. Several options are available for plugging the line, including using a specialized brake line plug or simply clamping it with hose pliers. Another option is to use a ziplock bag and rubber band combination by cutting off one corner of a small ziplock bag and fitting it tightly over the open end before securing it with a rubber band. It’s worth noting that sometimes just removing and replacing parts like callipers won’t necessarily require flushing or bleeding your brakes unless air gets into your lines. However, if you’re changing out components near where lines connect (like master cylinders), then this could slow down progress without properly isolating them from other areas using the plugs covered above.Why Are My ABS and Brake Lights On Even If There Are No Error Codes?

If you’re wondering about the reasons for abs and brake light illuminating without any error codes, it could be due to various factors. It is possible that there is a problem with the electrical wiring or sensors, resulting in a false signal being sent to the ABS and brake system. Additionally, a malfunctioning ABS control module or a faulty wheel speed sensor could also be the cause. Seeking professional assistance may help diagnose and resolve the issue.

Safety Precautions To Keep In Mind

When removing brake lines from callipers, always wear protective gloves and eyewear to prevent contact with brake fluid. Be cautious when using certain materials near brake fluid, such as painted surfaces or plastic parts. Remember to collect any spilt fluid in a catch basin or container.Wearing Protective Gear

As someone who works with automotive parts, I understand the importance of wearing protective gear when working on brake systems. Here are some items to consider when preparing for a brake line removal:- Eye protection: Brake fluid can cause serious irritation and damage to your eyes, so it’s important to wear goggles or safety glasses.

- Gloves: Brake fluid is corrosive and can harm your skin, so it’s recommended to wear nitrile gloves that are resistant to chemicals.

- Protective clothing: Wear long-sleeved shirts and pants to avoid direct exposure to brake fluid.

- Respirator mask: If you’re working in an enclosed area, such as inside a garage, using a respirator mask can prevent inhalation of fumes from the brake fluid.

Being Cautious With Brake Fluid Near Certain Materials

When working with brake fluid, it’s important to be cautious around certain materials. Brake fluid is highly corrosive and can damage some surfaces if improperly handled. For instance, you should avoid getting brake fluid on your skin or clothing as it can cause chemical burns and ruin fabrics. Another material that requires caution when handling brake fluid is rubber. Over time, exposure to brake fluid can cause rubber components like hoses and seals to deteriorate and leak. Taking these precautions when handling brake fluid near certain materials will help preserve your vehicle’s parts while protecting yourself from potential harm. Always wear protective gear such as gloves and goggles for spills or splashes.Collecting Any Spilled Fluid In A Catch Basin Or Container

When working with brake fluid, I always keep a catch basin or container handy. Inevitably, some fluid may spill out while removing the brake line from the calliper. It’s important to collect any spilt fluid in a container so that it can be properly disposed of later. While changing my brake pads, I accidentally knocked over an open bottle of brake fluid onto the garage floor. Luckily, I had a catch basin nearby and could quickly clean up the mess before any harm was done.Can I Test a Fuel Pressure Regulator Without a Gauge?

When it comes to testing fuel pressure regulator without a gauge, it can be challenging. A gauge is necessary to accurately measure the pressure. Without it, you may not get reliable results. A gauge helps you identify issues with fuel pressure and determine if the regulator is functioning optimally. So, it’s best to use a gauge for testing fuel pressure regulator effectively.

When removing brake lines from callipers, always wear protective gloves and eyewear to prevent contact with brake fluid. Be cautious when using certain materials near brake fluid, such as painted surfaces or plastic parts. Remember to collect any spilt fluid in a catch basin or container.Wearing Protective Gear

As someone who works with automotive parts, I understand the importance of wearing protective gear when working on brake systems. Here are some items to consider when preparing for a brake line removal:- Eye protection: Brake fluid can cause serious irritation and damage to your eyes, so it’s important to wear goggles or safety glasses.

- Gloves: Brake fluid is corrosive and can harm your skin, so it’s recommended to wear nitrile gloves that are resistant to chemicals.

- Protective clothing: Wear long-sleeved shirts and pants to avoid direct exposure to brake fluid.

- Respirator mask: If you’re working in an enclosed area, such as inside a garage, using a respirator mask can prevent inhalation of fumes from the brake fluid.