Understanding Fuel Evaporation Leakage Check

Fuel evaporation leakage is the release of fuel vapours from the fuel system due to a deficiency in its components or a broken seal, resulting in an environmental hazard, safety concerns, and increased fuel consumption.Definition And Causes

Fuel evaporation leakage, also known as an evaporative emissions (EVAP) leak, occurs when volatile fuel vapours escape from the vehicle’s fuel system into the atmosphere.These leaks are typically caused by damaged or deteriorated components within the EVAP system, designed to capture and contain these harmful emissions before releasing them into the environment.Under normal circumstances, a properly functioning EVAP system captures raw fuel vapours produced during gasoline storage and combustion.It then redirects these vapours back into your engine for burning instead of allowing them to enter the atmosphere.However, when your vehicle develops a flaw in its EVAP system due to wear and tear or manufacturing defects, these toxic gases can seep out unchecked—an issue that contributes significantly to air pollution and reduces overall fuel efficiency.Types Of Fuel Evaporation Leakage

There are two main types of fuel evaporation leakage, which are:- Gross Evaporative Emissions: This type of leak is usually caused by a punctured or damaged fuel tank or by a loose or missing fuel cap. A gross leak allows more than 0.04 inches of mercury emission in 2 hours.

- Small Evaporative Emissions: This type of leak involves very small leaks that cannot be easily detected by the naked eye or with basic inspection equipment. These types of leaks are usually caused by issues with hoses, valves, and fittings and can cause Check Engine Light to turn on. They typically release less than 0.04 inches of mercury in 2 hours.

The Importance Of Checking For Fuel Evaporation Leakage

Checking for fuel evaporation leakage is crucial for several reasons: it helps reduce environmental impact, ensures safety while driving, and saves money on fuel costs.Environmental Impact

As an SEO and high-end copywriter, I believe that checking for fuel evaporation leakage is crucial to reducing the environmental impact caused by fuel emissions. An EVAP leak can release raw fuel vapour into the atmosphere, contributing to air pollution and climate change.Detecting and fixing an EVAP leak can reduce our carbon footprint and save on fuel costs in the long run.Regular inspections and maintenance of your vehicle’s fuel system are necessary to ensure it runs efficiently while minimizing its negative environmental impact.

An EVAP leak can release raw fuel vapour into the atmosphere, contributing to air pollution and climate change.Detecting and fixing an EVAP leak can reduce our carbon footprint and save on fuel costs in the long run.Regular inspections and maintenance of your vehicle’s fuel system are necessary to ensure it runs efficiently while minimizing its negative environmental impact.Safety Concerns

Ensuring that your vehicle’s fuel system is in good working order isn’t just important for protecting the environment and saving money; it can also be a major safety concern. A leaking fuel evaporation system can release harmful hydrocarbon vapours into the atmosphere, contributing to air pollution and increasing fire risk.These volatile fumes can ignite with an open flame or spark, leading to potential fires or explosions.That’s why it’s vital to regularly inspect and maintain your vehicle’s fuel system to prevent any leaks from occurring.By following proper maintenance procedures such as checking for damage around O-rings or hoses, replacing any worn-out parts promptly, like purge valve or solenoid valve, when necessary and keeping your tank clean of debris, you’ll be able to detect early signs of any problems before they become serious safety hazards.

A leaking fuel evaporation system can release harmful hydrocarbon vapours into the atmosphere, contributing to air pollution and increasing fire risk.These volatile fumes can ignite with an open flame or spark, leading to potential fires or explosions.That’s why it’s vital to regularly inspect and maintain your vehicle’s fuel system to prevent any leaks from occurring.By following proper maintenance procedures such as checking for damage around O-rings or hoses, replacing any worn-out parts promptly, like purge valve or solenoid valve, when necessary and keeping your tank clean of debris, you’ll be able to detect early signs of any problems before they become serious safety hazards.Cost Savings

One of the benefits of checking for fuel evaporation leakage is that it can lead to cost savings. A leaking EVAP system can cause a decrease in fuel economy, with gas mileage dropping by as much as 30 per cent.This means you’ll end up spending more money on gasoline than necessary.By performing regular inspections and maintenance on your vehicle’s fuel delivery system, you can prevent these costly issues from occurring.This includes properly using your fuel cap and regularly cleaning out your fuel tank to ensure everything functions correctly.Can Fuel Evaporation Leakage Cause the Fuel Pump to Not Prime Correctly?

Can fuel evaporation leakage cause the fuel pump to not prime correctly? In some situations, the answer is yes. When there is a fuel evaporation leakage issue, it can lead to a drop in fuel pressure, causing the fuel pump to struggle with priming. If the fuel pump won’t prime properly, it can result in poor fuel delivery to the engine, affecting overall performance.

How To Check For Fuel Evaporation Leakage

To detect fuel evaporation leakage, the inspection process involves using specialized equipment to perform a pressure or smoke test and a thorough visual examination of common problem areas; continue reading to learn about prevention and maintenance techniques that can help you catch potential leaks early on.Inspection Process And Equipment Needed

As an experienced mechanic, I want to share the proper method for inspecting your vehicle’s fuel evaporation system.Here are the steps and equipment you will need:- OBDII Scanner: This tool is necessary to retrieve diagnostic trouble codes (DTCs) related to the fuel system.

- Smoke Test Machine: This machine introduces smoke into the fuel system to help locate leaks.

- Fuel Cap Tester: This tool ensures the gas cap functions properly and seals the fuel tank.

- Professional-Grade Inspection Light: A bright light helps illuminate hard-to-see areas of the fuel system.

- Visual Inspection: Look for damaged hoses, loose or missing clamps, and cracked or corroded fittings.

- Pressure Test: Use a pressure tester to apply pressure to your vehicle’s fuel tank while monitoring real-time pressure changes.

- Outlet Side Assessment: Inspect the outlet side of your vehicle’s EVAP canister and check for any signs of damage, including cracks, corrosion or breaks.

- Purge Valve/Solenoid Valve Check: Verify that each valve functions properly with a voltmeter and by listening closely for clicking sounds during operation.

- Vent Control Valve Check: Check this valve by applying power with a scan tool or battery power source, then applying a vacuum on one port and using scanning tools to check codes from it.

Common Areas To Check

When checking for fuel evaporation leakage, it is important to inspect the following areas:- Fuel Cap: A loose or damaged fuel cap can cause an EVAP leak. Inspect the cap and replace it if necessary.

- Fuel Lines and Hoses: Look for signs of wear or damage in the fuel lines and hoses, including cracks, leaks, or kinks.

- Charcoal Canister: The charcoal canister is a crucial component of the EVAP system. Make sure it is clean and in good condition.

- Purge Valve: The purge valve regulates vapour flow into the engine for combustion. Check for any damage or leaks.

- Vent Control Valve: This valve allows air to enter the fuel tank to prevent a vacuum from forming when the engine consumes fuel. Inspect for any issues with this valve.

- Vacuum Lines: Look for signs of wear or damage in any vacuum lines connected to the EVAP system.

Visual Inspection

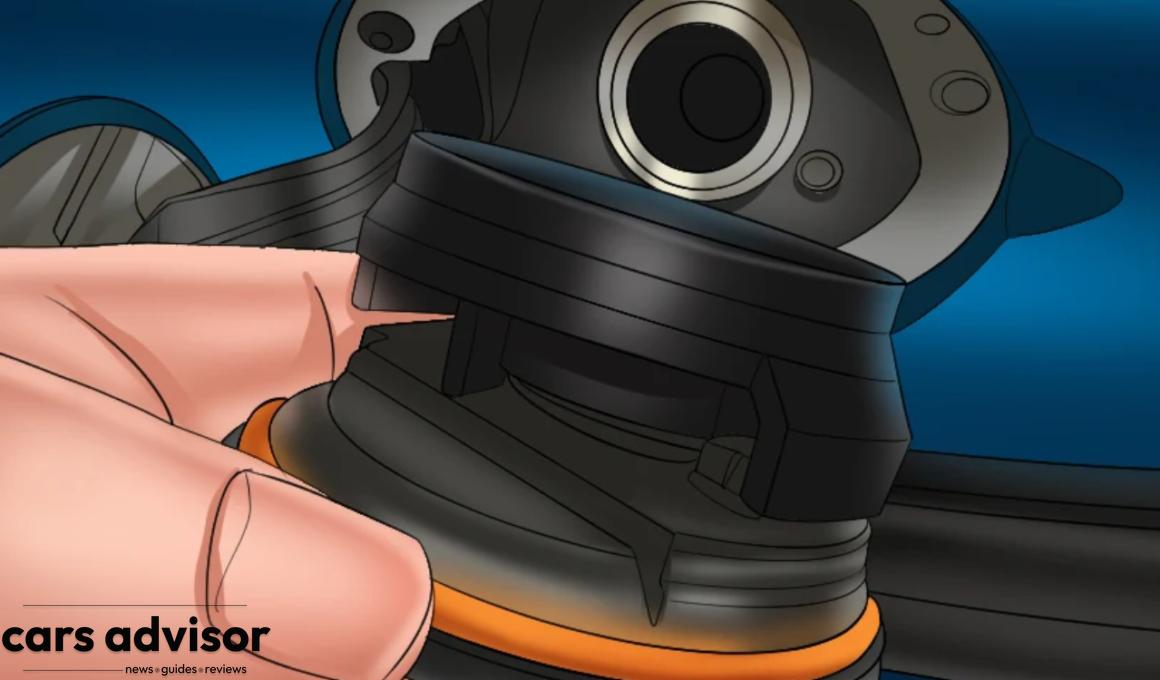

A visual inspection can be performed as part of the process to check for fuel evaporation leakage. This involves examining different fuel system components for any visible signs of damage or leaks.During this inspection, looking at hoses, fittings, and valves for cracks, corrosion, or looseness that may indicate possible leaks is essential.One way to identify potential issues during this visual inspection is by looking for wet spots around the fuel tank area. Some cars come equipped with a plastic shroud underneath where any dripping oil may have collected over time.Additionally, you can use a flashlight to get better visibility around hard-to-see areas like hoses behind manifolds and under covers.Pressure Test

Another method of checking for fuel evaporation leakage is through a pressure test. This involves applying pressure to the fuel system and observing whether or not there are any leaks.During the pressure test, different fuel system parts will be checked, including the lines and hoses leading to and from the fuel tank.By performing regular pressure tests as part of your maintenance routine, you can identify potential issues before they become major problems.It’s important to note that results may vary based on the make and model of your vehicle since different manufacturers have unique testing requirements.Smoke Test

The smoke test is a common method used to check for fuel evaporation leakage. This involves introducing smoke into the intake system or fuel tank and observing for any signs of smoke escaping from a leak.During a smoke test, technicians use specialized equipment to introduce non-toxic, thick white smoke throughout the engine’s vacuum hoses and other areas prone to leaks.The smoke will seep through any leaks in the fuel system, making it easy to pinpoint their exact location.Using a combination of EVAP leak detection methods like this can help ensure early identification of small problems before they become major issues affecting performance and overall efficiency.Prevention And Maintenance

To prevent fuel evaporation leakage, it’s essential to conduct regular inspections and maintenance, use the proper fuel cap, clean the fuel tank routinely, and replace damaged parts promptly.Regular Inspection And Maintenance

Regular inspection and maintenance of your vehicle’s fuel system can prevent fuel evaporation leakage and ensure proper function.Here are some steps to take:- Check the gas cap regularly to ensure it is properly tightened and sealed.

- Schedule regular fuel tank cleaning to remove debris and buildup that can cause leaks.

- Replace damaged or worn parts such as O-rings, hoses, or valves.

- Have a professional mechanic inspect a fuel system using an EVAP leak detection tool.

- Clean the fuel injectors and diagnose any issues with the fuel pump to ensure efficient fuel delivery.

- Evaluate the vapour recovery system for leaks or blockages.

Regular Fuel Tank Cleaning

As a fuel system inspection and maintenance professional, I understand the importance of regular fuel tank cleaning to prevent fuel evaporation leakage. Over time, sediment and debris can accumulate in your vehicle’s fuel tank, leading to clogs and even leaks if left unaddressed.In addition to improving overall fuel efficiency and extending the life of your vehicle’s parts, regularly scheduled fuel tank cleanings can save you money on costly repairs.A dirty or clogged fuel system can cause engine stalling or decreased performance, leading to significant repair costs.Replacing Damaged Parts

If the inspection reveals that certain parts of the fuel system are damaged or worn out, replacing them as soon as possible is important. This will prevent leaks from occurring in the future and ensure that your vehicle runs safely and efficiently.Here are some parts that may need to be replaced:- Fuel Tank: If the fuel tank is cracked or otherwise damaged, it may need to be replaced entirely.

- Fuel Lines: Over time, fuel lines can become clogged with debris or crack due to exposure to heat and other elements. Replacing them ensures proper fuel flow and prevents leakage.

- Charcoal Canister: The charcoal canister is a key component of the EVAP system, and if it becomes damaged or clogged, it can cause a range of issues, including engine stalling and reduced fuel economy.

- Purge Valve: The purge valve regulates the flow of vapours between the EVAP system and the engine intake manifold. A damaged valve can cause issues with emission control and trigger the Check Engine Light.

- Vent Control Valve: The vent control valve controls airflow into and out of the fuel tank during refuelling. A faulty valve can cause excessive pressure buildup in the tank and increase emissions output.