Welcome to the world of 6.7 Cummins engines and fuel rail plugs! Are you looking for ways to optimize your diesel engine’s performance, increase fuel efficiency, and reduce emissions? You’ve come to the right place.

In this blog, we will explore the numerous benefits of installing a fuel rail plug on your powerful 6.7 Cummins engine by discussing its functions, advantages, and impact on both performance and environmental concerns.

Understanding The 6

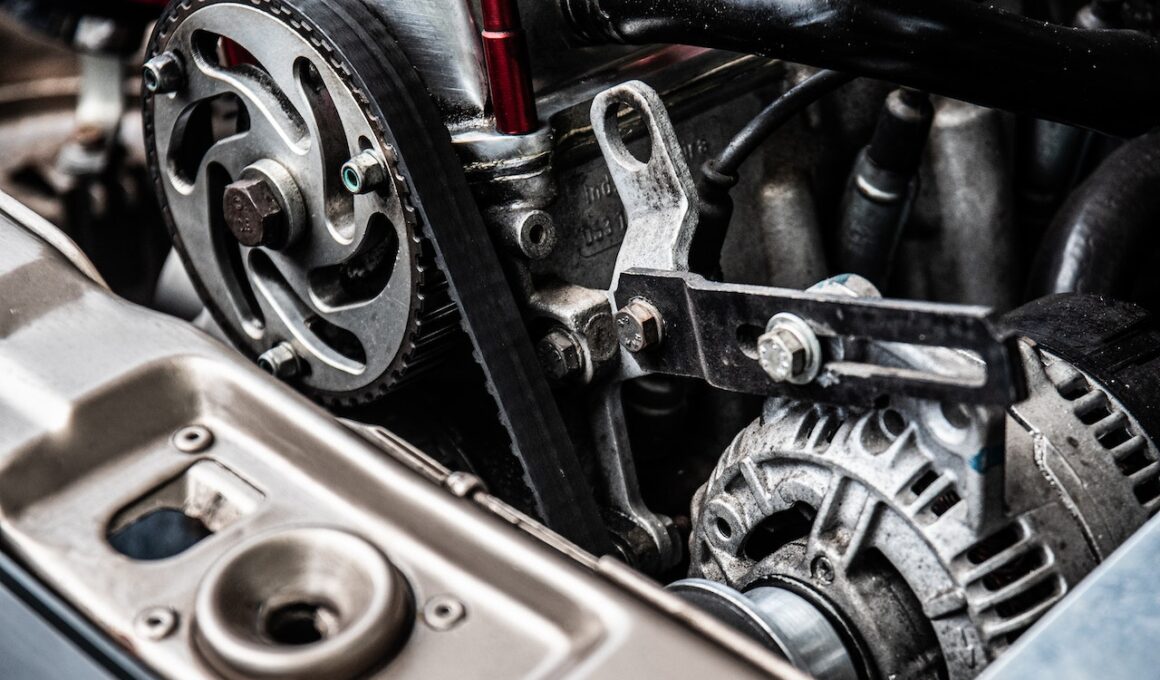

The 6.7 Cummins fuel rail plug is a component that replaces the fuel rail pressure relief valve (FRPRV) and helps to maintain commanded rail pressure, resulting in increased engine performance and fuel efficiency.

Definition And Function Of A Fuel Rail Plug

As a dedicated diesel enthusiast, I’m always exploring ways to optimize the performance of my 6.7 Cummins engine. One component that has piqued my interest is the fuel rail plug, which serves an essential function in any high-performance diesel setup.

Essentially, a fuel rail plug is a small but vital component installed into the factory fuel system to replace or eliminate the pressure relief valve (PRV). The PRV’s main purpose is to maintain proper pressure within your 6.7 Cummins engine’s common rail system by releasing excess pressure when it gets too high.

The use of a quality fuel rail plug eliminates these problems by maintaining consistent high pressure within your engine’s fuel rails throughout its operation for better overall efficiency and power delivery.

In conclusion – installing an efficient fuel rail plug on your 6.7 Cummins engine can provide significant benefits like smoother power output and increased performance potential while preventing any undue stress on important internal components due to fluctuations in fuel pressures or temperatures caused by failing stock valves like FRPRVs (Fuel Rail Pressure Relief Valves) found on some models suffering from manufacturing flaws.

Common Types Of Fuel Rail Plugs

There are a few common types of fuel rail plugs that you can use for your 6.7 Cummins engine, each with its own set of advantages and disadvantages:

- Metal Spring Fuel Rail Plug: This type of fuel rail plug is made of metal and has a spring mechanism that regulates the pressure inside the fuel rail. It is durable and long-lasting, but it may not be as effective in preventing leaks as other types.

- Metal Diaphragm Fuel Rail Plug: Similar to the metal spring plug, this type also uses a metal construction but with a diaphragm instead of a spring mechanism. It provides better sealing capabilities than the spring plug but may not be as durable.

- XDP Race Fuel Valve: This fuel valve replaces both the stock pressure relief valve and banjo bolt. It allows for adjustments to fuel pressure while also providing peace of mind against any potential leaks or failures.

- Shims: Instead of plugging, shimming involves adding thin washers between the fuel rail and its mounting points to prevent any odd pressure spikes from affecting injectors.

It’s important to consider the pros and cons of each type before deciding which one works best for your needs.

Advantages And Disadvantages Of Different Fuel Rail Plug Options

When it comes to fuel rail plug options for your 6.7 Cummins engine, there are several options available, each with its own advantages and disadvantages. To help you make an informed decision, here’s a comparison of the different fuel rail plug options in an easy-to-understand HTML table format.

| Fuel Rail Plug Option | Advantages | Disadvantages |

|---|---|---|

| BD Common Rail Fuel Plug |

|

|

| ATS Fuel Rail Pressure Plug |

|

|

| Replacement of Stock Banjo Bolt with Rail Plug |

|

|

| Shimming |

|

|

Each fuel rail plug option has its merits and drawbacks, so make sure to consider your specific needs and preferences, as well as the recommendations of experts and other Cummins owners, before making a decision.

Benefits Of Installing A Fuel Rail Plug On Your 6

Installing a fuel rail plug on your 6.7 Cummins engine can provide several benefits, including increased fuel efficiency, improved engine performance, reduced emissions and environmental impact, extended engine life, and minimizing fuel waste.

Increased Fuel Efficiency

One of the most significant benefits of installing a fuel rail plug on your 6.7 Cummins engine is an increase in fuel efficiency. By maintaining high pressure in the fuel system, the engine can operate at peak performance and consume less fuel overall.

For example, the BD Common Rail Fuel Plug eliminates the troublesome pressure relief valve and ensures commanded rail pressure for optimal fuel delivery. Additionally, using shims instead of plugs is recommended as it prevents any marring of critical surfaces that could cause problems down the line.

Improved Engine Performance

Installing a fuel rail plug in your 6.7 Cummins engine can offer significant improvements in engine performance. By allowing for consistent fuel pressure, the engine is able to operate at peak efficiency, resulting in better acceleration and overall power capability.

Not only does this modification enhance performance, but it also provides an added layer of protection against potential problems with the stock system such as the commonly reported manufacturer flaw on the Fuel Rail Pressure Relief Valve (FRPRV).

Reduced Emissions And Environmental Impact

As someone who cares about the environment, I am always looking for ways to reduce my carbon footprint. Installing a fuel rail plug on your 6.7 Cummins engine is one way to do just that.

In fact, using a fuel rail plug can lead to an emissions delete by preventing any fuel waste or leakage through the relief valve or banjo bolt during hard driving conditions.

This translates into reduced air pollution and improved overall environmental health. Not only that, but with increased efficiency comes less fuel consumption – saving you money at the pump while also benefiting the planet.

Extended Engine Life

One of the most significant benefits of installing a fuel rail plug on your 6.7 Cummins engine is that it can extend your engine’s life. This is because the fuel rail plug prevents unnecessary wear and tear caused by pressure relief valves, making sure that the commanded rail pressure is maintained at all times.

By eliminating leaks, reducing emissions and preventing fuel waste, you are also taking steps towards keeping your engine in better condition over time.

Moreover, using a fuel rail plug as part of regular maintenance for diesel performance upgrades or power modifications ensures consistent fuel efficiency, maintains proper injection control, and keeps environmental impact to a minimum while increasing torque output.

Minimizing Fuel Waste

As a 6.7 Cummins owner, I know the value of keeping my engine running efficiently and minimizing fuel waste. Installing a fuel rail plug is one effective way to achieve this goal.

Not only does this save money on gas, but it also helps reduce our impact on the environment by lowering emissions. And when it comes to performance upgrades or modifications, maintaining proper fuel pressure is key to maximizing power gains while still ensuring engine longevity and reliability.

Installation And Maintenance Of The 6

Proper installation procedures and regular maintenance are crucial for the effective use of the 6.7 Cummins fuel rail plug; it is important to follow manufacturer instructions and troubleshoot common issues to ensure optimal performance.

Proper Installation Procedures

To ensure that the fuel rail plug is installed correctly, it is essential to follow the step-by-step guide below:

- Begin by disconnecting the negative battery cable and removing the engine cover.

- Locate the fuel rail pressure relief valve (FRPRV) and use a socket wrench to remove it.

- Install the fuel rail plug in place of the FRPRV using an adjustable wrench or socket wrench.

- Use a torque wrench to tighten the fuel rail plug with 50-60 ft-lbs of torque, following manufacturer guidelines for proper placement.

- Reconnect the negative battery cable and turn on your vehicle to check for any leaks from the new fuel rail plug.

- Monitor your vehicle’s performance, such as its fuel efficiency, emissions levels, engine performance, and longevity.

- After installation, perform regular maintenance checks on your Cummins engine to ensure that everything is working correctly.

By following these proper installation procedures, you can be confident that your fuel rail plug will perform effectively and efficiently in your 6.7 Cummins engine while also extending its lifespan and saving you money over time.

Regular Maintenance Requirements

As with any vehicle component, proper maintenance is key to ensuring optimal performance of your fuel rail plug. Here are some regular maintenance requirements for the 6.7 Cummins fuel rail plug:

- Inspect the fuel rail plug regularly to ensure it is clean and free of debris or damage.

- Check for any signs of leaks or fuel waste around the fuel rail plug.

- Perform periodic torque checks on the fuel rail plug to ensure it is still properly tightened.

- Monitor your engine’s performance and watch for any symptoms that may indicate a malfunctioning fuel rail system, such as decreased power or poor fuel efficiency.

- Keep your engine’s overall maintenance up-to-date to ensure its longevity and optimal performance.

By following these routine maintenance tasks, you can help prevent issues with your 6.7 Cummins engine’s fuel system and maximize its efficiency and lifespan.

Troubleshooting Common Issues

As with any engine upgrade or modification, there may be issues that arise when installing a fuel rail plug on a 6.7 Cummins engine. Here are some common troubleshooting tips:

- Fuel rail shims must be used in place of the fuel rail plug to prevent marring and ensure proper pressure.

- Check the torque specs for your specific fuel rail plug and make sure it is tightened to the proper amount.

- If you notice anything unusual with your engine after installing the fuel rail plug, such as decreased fuel efficiency or strange noises, check for fuel leakage around the plug area.

- Sometimes the vehicle’s computer may still show trouble codes related to the FRPRV even after installing a fuel rail plug. In this case, try resetting your vehicle’s computer or contacting a professional mechanic for further assistance.

- Always follow proper maintenance procedures and regularly check for any signs of wear or damage on your fuel rail plug.

By following these simple tips, you can help ensure that your 6.7 Cummins engine runs smoothly and efficiently with a properly installed and maintained fuel rail plug.

Frequently Asked Questions And Conclusion

In conclusion, installing a fuel rail plug on your 6.7 Cummins engine can provide numerous benefits, including increased fuel efficiency, improved engine performance, reduced emissions and environmental impact, extended engine life, and minimized fuel waste.

Proper installation procedures and regular maintenance are crucial to ensure the longevity of your engine’s fuel system. By eliminating troublesome pressure relief valves and preventing leaks caused by stock banjo bolts or manufacturer flaws, a high-quality fuel rail plug like the BD Common Rail Fuel Plug or ATS Fuel Rail Pressure Plug can give you peace of mind while driving.

Shimming is recommended over plugging to prevent marring and spikes damaging injectors.